Rods

Our webs are standard equipped with rods of spring steel class C (DIN 17228). However we can also mount rods of CrSi-steel, stainless steel or glass fibre . After consultation with you, we can also use other materials so that the produced web will meet your expectations as good as possible.

Without using rod coverings we can create gaps with a minimum of 5mm. By using rod covering we can reduce the gaps to 2mm.

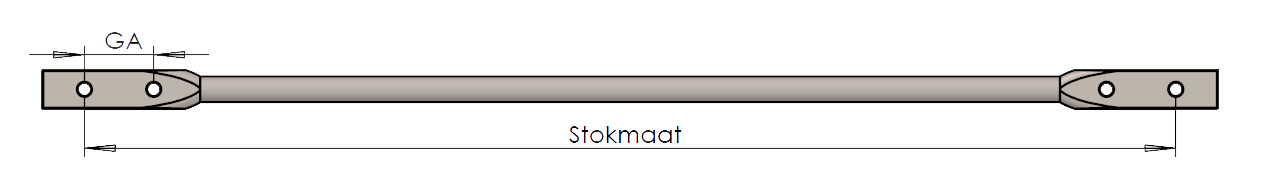

Stokmaat

In determining the correct width of the sieve web, it is important that the rods have the correct “stokmaat”. This is the distance between the two outside rivet holes, C.T.C. When ordering loose rivet rods it is important that you mention the stokmaat as well as the distance between the holes in one end. Without further notice, we assume this distance to be 20mm in 50mm wide traction belts and 32mm in 60 or 75mm wide traction belts. On request we can also make these distances 24 or 30mm

Rivet rods

Standard rivet rods are available in diameters 6, 7, 8, 9, 10, 11, 12, 13 and 15mm. standard rods can be made from springsteel, CrSi-steel, stainless-steel or glassfibre. To protect the product from damaging or to minimise the gap, rods can be covered.

Twin rods

For the processing of small products, such as flower bulbs, we produce webs with “twin rods”. A twin rod consists of 2 rods, which are clamped together at their ends in a tube. The actual pitch is half of the belt pitch. With the use of rod covering we can create a gap as small as 2mm.

Vulcanised rods

To protect the product from damage, we can vulcanize a soft rubber layer onto the rods. This rubber has a hardness of 30-35° shore. Because the rod is vulcanized over the total length, including the flattenings, this offers optimal protection. With these rods, the centre belt is attached with OGP.