Drive wheels

The sprocket code consists of the following elements:

Pitch/ number of teeth + type

M = with support fingers

S = with closed belt support

Z = without belt support

N = finger wheel for high cam traction belts

G = combination wheel suitable for every type of traction belt

K = cage roller

All sprockets are splittable (unless otherwise stated) and therefore easy to assemble.

Low profile belts (types S and DS) can also be driven by friction rollers. These are cage rollers (type K) and rubber rollers (type RR). It is essential that the web is tightly held around the roller. If necessary, this can be done by fitting a pressure roller near the drive roller.

Sprocket type M

With the Type M u can drive webs through teeth that drive in the bars , together with a belt support consists of a set of fingers.

Sprocket type N

Sprockets type N are suitable for driving high cam belts. These sprockets give a secure drive, without wear on the rods of the sieve web. Sprockets type N can be supplied without a flange, so that they can be assembled to drive the centre belt.

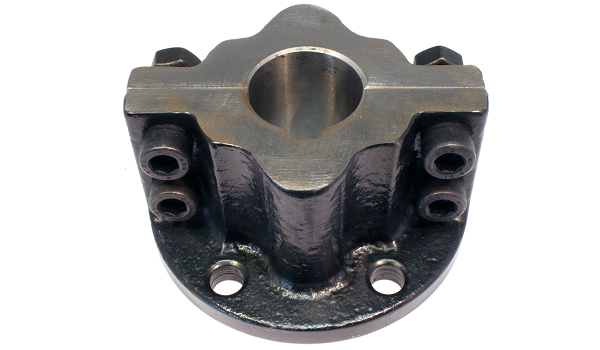

Sprocket type K

Cage rolers are ideal in combination with light sieve webs. Due to their small size they are very easy to handle and extremely efficient in use. Cage rolers, besides non- splittable, have a standard flange (also available without) and with the same options as other sprockets available.